Intelligent Compaction or IC involves the use of an accelerometer to measure changes in the amplitude wave of a vibratory asphalt roller or soil compactor. The rate of change in the amplitude wave measures the stiffness of the material being compacted. This stiffness value, when compared with the location of the drum(s) as measured using high-precision positioning systems, creates a map of your jobsite identifying potential “soft” or weak spots in the compacted material. Knowing these soft spots allows for spot-checking of the material to ensure uniform compaction, thereby verifying the integrity of the compaction process.

Through the location mapping process, Intelligent Compaction is also presenting a full map of your roller passes over the entire area being compacted. This allows verification that (a) your operators are performing in the most efficient roller patterns possible; (b) you are achieving uniform compaction through pass-count measurement and coverage; (c) of the minimum pass-count needed for achieving target quality assurance measurements.

For asphalt applications, an optional SAKAI temperature sensor can also be added to map the temperature of the asphalt mat during the compaction process, ensuring that your roller operators are able to keep pace with the paver and stay off the mat outside the tender zone temperature range.

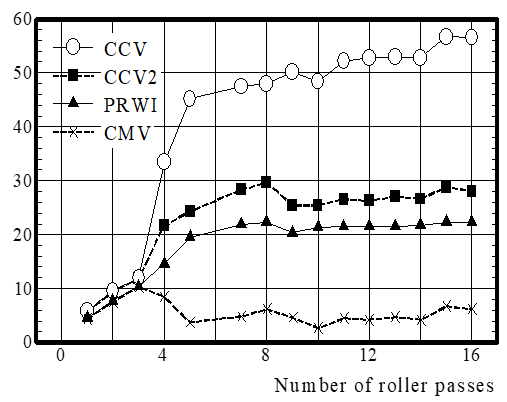

SAKAI has partnered with the industry’s leading manufacturers of intelligent compaction systems to ensure the best fitment and performance possible. Our proprietary CCV sensor can be used with Topcon systems. The SAKAI CCV sensor (Compaction Control Value) is more accurate than conventional CMV sensors in that it tracks with actual density as pass count increases. In contrast, the common CMV sensor accuracy falls off as pass count increases. Because of this, SAKAI CCV was the first IC measurement value to meet Federal Highway Administration criteria.